Njengempahla yepayipi esetshenziswa kabanzi, ipayipi yensimbi ye-ductile idlala indima ebalulekile emikhakheni eminingi. Kodwa-ke, ukukalwa kwesivinini somsindo we-ultrasonic kunikeza indlela eyaziwayo nethembekile embonini yokuqinisekisa ubuqotho bezingxenye.

1. Ipayipi le-iron le-Ductile kanye nokusetshenziswa kwalo

I-DINSENipayipi le-iron ductileiyipayipi elenziwe ngensimbi ye-ductile ngenqubo ye-centrifugal casting. Inezinzuzo zamandla aphezulu, ukuqina okuphezulu, ukumelana nokugqwala, ukumelana nomfutho ophakeme, njll., futhi isetshenziswa kakhulu ekuhlinzekeni kwamanzi emadolobheni, i-drainage, ukudluliswa kwegesi neminye imikhakha.

Ezinhlelweni zokuhlinzeka ngamanzi emadolobheni, amapayipi ensimbi e-ductile angakwazi ukumelana nomfutho wamanzi ophezulu ukuze kuqinisekiswe ukuthuthwa okuphephile kwemithombo yamanzi. Ukumelana nokugqwala kwayo okuhle kuyenza ingakwazi ukuguguleka ngenxa yokungcola okusemanzini ngesikhathi sokusetshenziswa isikhathi eside, okunweba impilo yesevisi yepayipi. Ehlelweni lokudonsa amanzi, amandla aphezulu kanye nokuqina kwamapayipi ensimbi e-ductile angakwazi ukumelana nokukhuculwa kwendle kanye nesenzo samandla angaphandle ukuze kuqinisekiswe ukusebenza okuzinzile kwesistimu yokudonsa amanzi. Ngaphezu kwalokho, amapayipi e-iron ductile nawo adlala indima ebalulekile emikhakheni efana nokudluliswa kwegesi. Ukuvalwa kwawo okuhle kungavimbela ngempumelelo ukuvuza kwegesi futhi kuvikele izimpilo zabantu kanye nempahla.

2. Izindlela nezizathu zokuthola izinga le-spheroidization lamapayipi ensimbi e-ductile

Izindlela zokutholwa

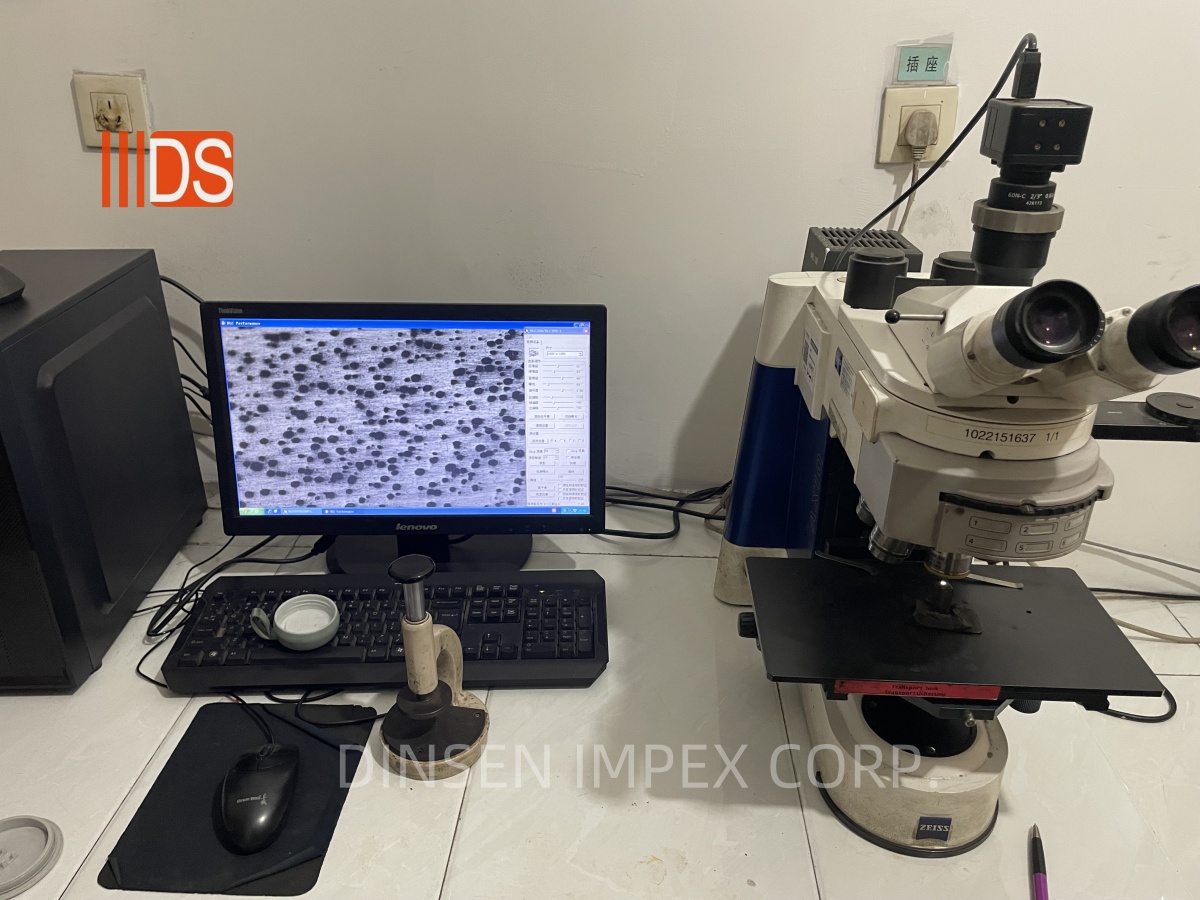

Indlela yokuhlaziya i-Metallographic: Lena indlela evame ukusetshenziswa yokuthola izinga le-spheroidization. Ngokulungiselela amasampula e-metallographic amapayipi ensimbi eyi-ductile, i-morphology kanye nokusatshalaliswa kwe-graphite kubukwa ngaphansi kwesibonakhulu ukuze kunqunywe izinga le-spheroidization. Izinyathelo eziqondile zifaka amasampula, ukufaka inlaying, ukugaya, ukupholisha, ukugqwala nokubona. Indlela yokuhlaziya i-metallographic ingakwazi ukubona ngokunembile izinga le-spheroidization ye-graphite, kodwa ukusebenza kuyinkimbinkimbi futhi kudinga imishini yobuchwepheshe kanye nochwepheshe.

Indlela yokuthola i-Ultrasonic: Izinga le-spheroidization litholwa ngokusebenzisa izici zokusakaza zamagagasi e-ultrasonic kumapayipi ensimbi e-ductile. Ijubane lokusabalalisa kanye nokuncishiswa kwamagagasi e-ultrasonic ku-ductile iron enamazinga ahlukene we-spheroidization ahlukile. Ngokulinganisa imingcele yamagagasi e-ultrasonic, izinga le-spheroidization lingachazwa. Le ndlela inezinzuzo zokuba iyashesha, ingabhubhisi futhi inembe, kodwa idinga imishini yokuhlonza i-ultrasonic yobungcweti nesofthiwe.

Indlela yokuhlaziya okushisayo: Izinga le-spheroidization linqunywa ngokulinganisa izinguquko ezishisayo zamapayipi ensimbi edonsayo ngesikhathi sokupholisa. I-Ductile iron ene-spheroidization enhle izoba namajika athile okushintsha okushisayo ngesikhathi sokupholisa. Ngokuhlaziya lawa majika, izinga le-spheroidization linganqunywa. Ukuhlaziywa kwe-thermal kunezinzuzo zokusebenza okulula nesivinini esisheshayo, kodwa ukunemba kwayo kuphansi kakhulu.

Isizathu sokuhlola

Qinisekisa ikhwalithi yomkhiqizo: Izinga le-spheroidization lingenye yezinkomba ezibalulekile zekhwalithi yepayipi lensimbi edonsayo. Uma izinga le-spheroidization liphakeme, amandla, ukuqina kanye nokugqwala kwepayipi kuzoba ngcono. Ngokuhlola izinga le-spheroidization, kungaqinisekiswa ukuthi ikhwalithi yamapayipi ensimbi ye-ductile ihlangabezana nezidingo ezijwayelekile futhi inikeze abasebenzisi imikhiqizo ethembekile.

Lungiselela inqubo yokukhiqiza: Imiphumela yokuhlolwa kwezinga le-spheroidization ingabuyiselwa kubakhiqizi ukuze babasize bathuthukise inqubo yokukhiqiza. Isibonelo, uma izinga le-spheroidization liphansi, inani le-spheroidizer elengeziwe, izinga lokushisa lokusakaza namanye amapharamitha lingalungiswa ukuze kukhuliswe izinga le-spheroidization, ngaleyo ndlela kuthuthukiswe ikhwalithi yomkhiqizo.

Hlangana nezidingo zamakhasimende: Kwezinye izinkambu ezikhethekile, njengokudluliswa kwegesi enomfutho ophezulu, izinga le-spheroidization lamapayipi ensimbi edonsayo liphezulu kakhulu. Ngokuhlola izinga le-spheroidization, kungenzeka ukuhlangabezana nezidingo ezithile zamakhasimende futhi kuthuthukiswe ukuncintisana kwemakethe kwemikhiqizo.

3. Ilabhorethri ye-DINSEN inikeza ukuhlolwa kwesilinganiso se-ductile iron pipe spheroidization kumakhasimende aseRussia

Ngesonto eledlule, ilabhorethri ye-DINSEN inikeze izinsiza zokuhlola izinga lepayipi le-iron ductile spheroidization kumakhasimende aseRussia. Ngemva kokuthola ikhomishana yeklayenti, ngokushesha sahlela ithimba lochwepheshe lochwepheshe futhi sathuthukisa uhlelo lokuhlola olunemininingwane.

Okokuqala, sisebenzise inhlanganisela yokuhlaziya i-metallographic kanye nokuhlolwa kwe-ultrasonic ukwenza ukuhlolwa okuphelele kwepayipi lensimbi elidonsa amanzi. Imiphumela yokuhlaziywa kwe-metallographic ibonise ukuthi i-graphite epayipini le-iron ductile yayine-morphology enhle kanye nezinga eliphezulu le-spheroidization. Imiphumela yokuhlolwa kwe-ultrasonic nayo ibihambisana nemiphumela yokuhlaziywa kwe-metallographic, iphinde iqinisekise ukunemba kwemiphumela yokuhlolwa.

Okwesibili, sinikeze iklayenti umbiko wokuhlola onemininingwane eminingi, okuhlanganisa indlela yokuhlola, imiphumela yokuhlolwa, iziphetho zokuhlaziya, njll. Iklayenti laneliseke kakhulu ngenkonzo yethu yokuhlola futhi lathi lizoqhubeka nokubambisana nathi.

Ngale nsizakalo yokuhlola, asizange sinikeze amakhasimende aseRussia kuphela imiphumela yokuhlolwa yekhwalithi ephezulu, kodwa futhi sanqwabelana nolwazi olucebile ekuhloleni izinga le-spheroidization lamapayipi ensimbi e-ductile. Sizoqhubeka nokusebenza kanzima ukuze sinikeze amakhasimende izinsiza zokuhlola ezinobuchwepheshe nezisebenza kahle futhi sibambe iqhaza ekuthuthukisweni kwemboni yamapayipi ensimbi edonsa amanzi.

Ngamafuphi, ukuhlolwa kwesilinganiso se-spheroidization samapayipi ensimbi e-ductile kuyindlela ebalulekile yokuqinisekisa ikhwalithi yomkhiqizo, ukuthuthukisa izinqubo zokukhiqiza, kanye nokuhlangabezana nezidingo zamakhasimende.I-DINSENIlabhorethri izoqhubeka nokuhlinzeka amakhasimende ngezinsizakalo zokuhlola ezinobuchwepheshe futhi ifake isandla ekuthuthukisweni kwemboni yamapayipi ensimbi edonsa amanzi.

Isikhathi sokuthumela: Dec-17-2024